Estimating the climate impact of an annual Mill Membership

Estimating the climate impact of an annual Mill Membership

Background

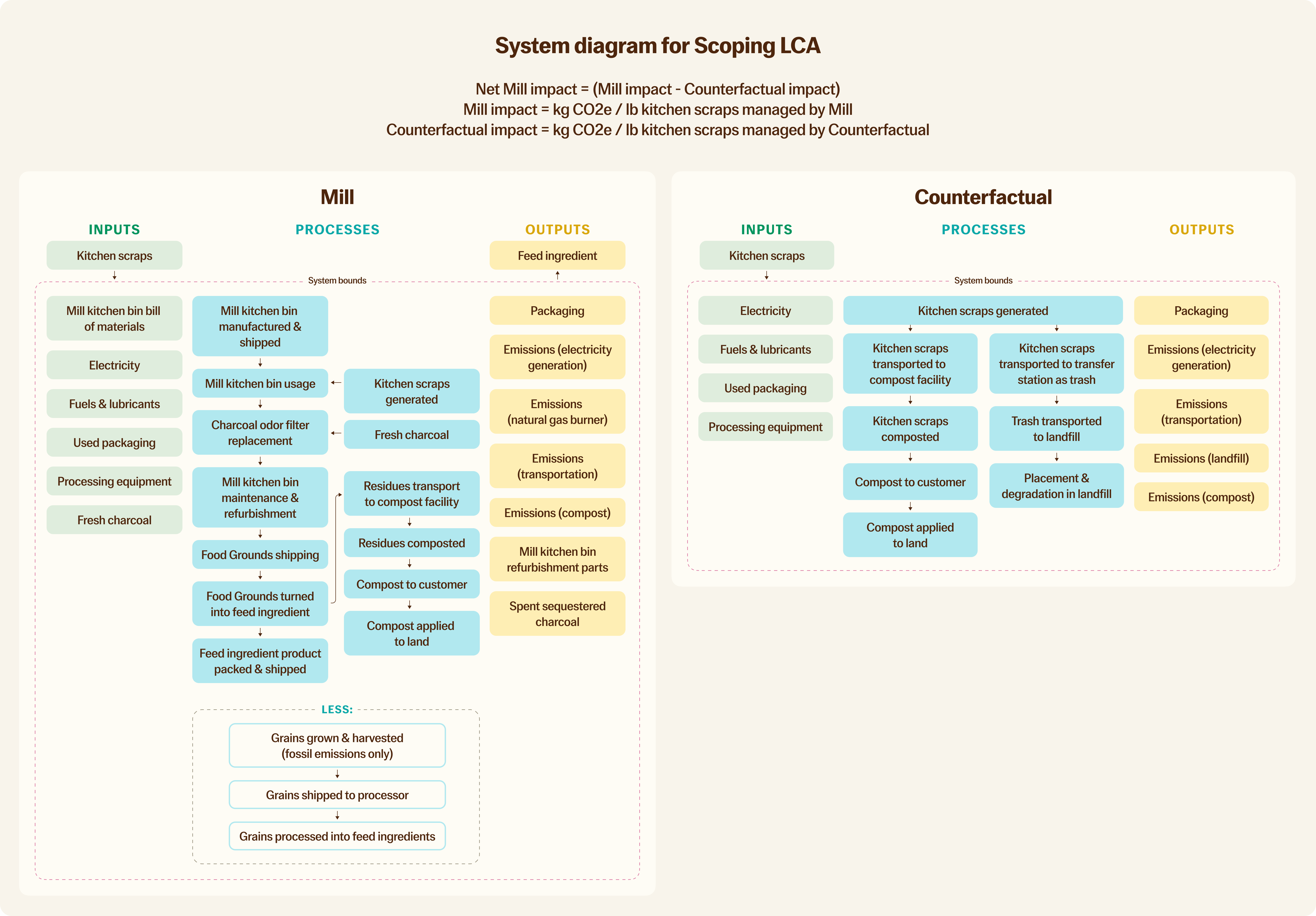

the global warming potential of carbon dioxide over a 20-year period.Scoping LCA

External validation

Approach

1

Scenario

Operations

Assumptions

2

Scenario 1

Near-term

Conservative

3

Scenario 2

Near-term

Optimistic

4

Scenario 3

Long-term

Conservative

5

Scenario 4

Long-term

Optimistic

There are no rows in this table

Considerations

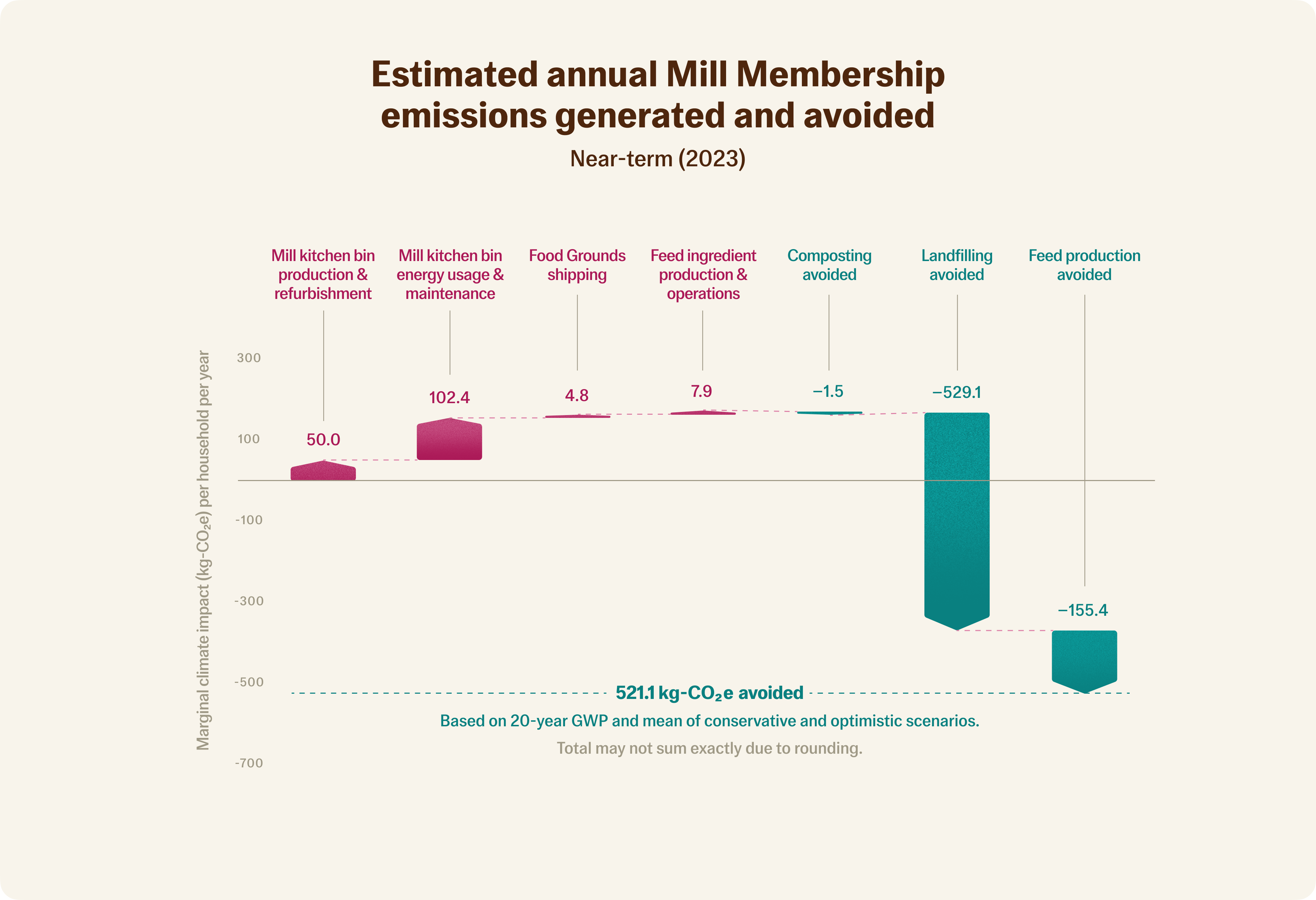

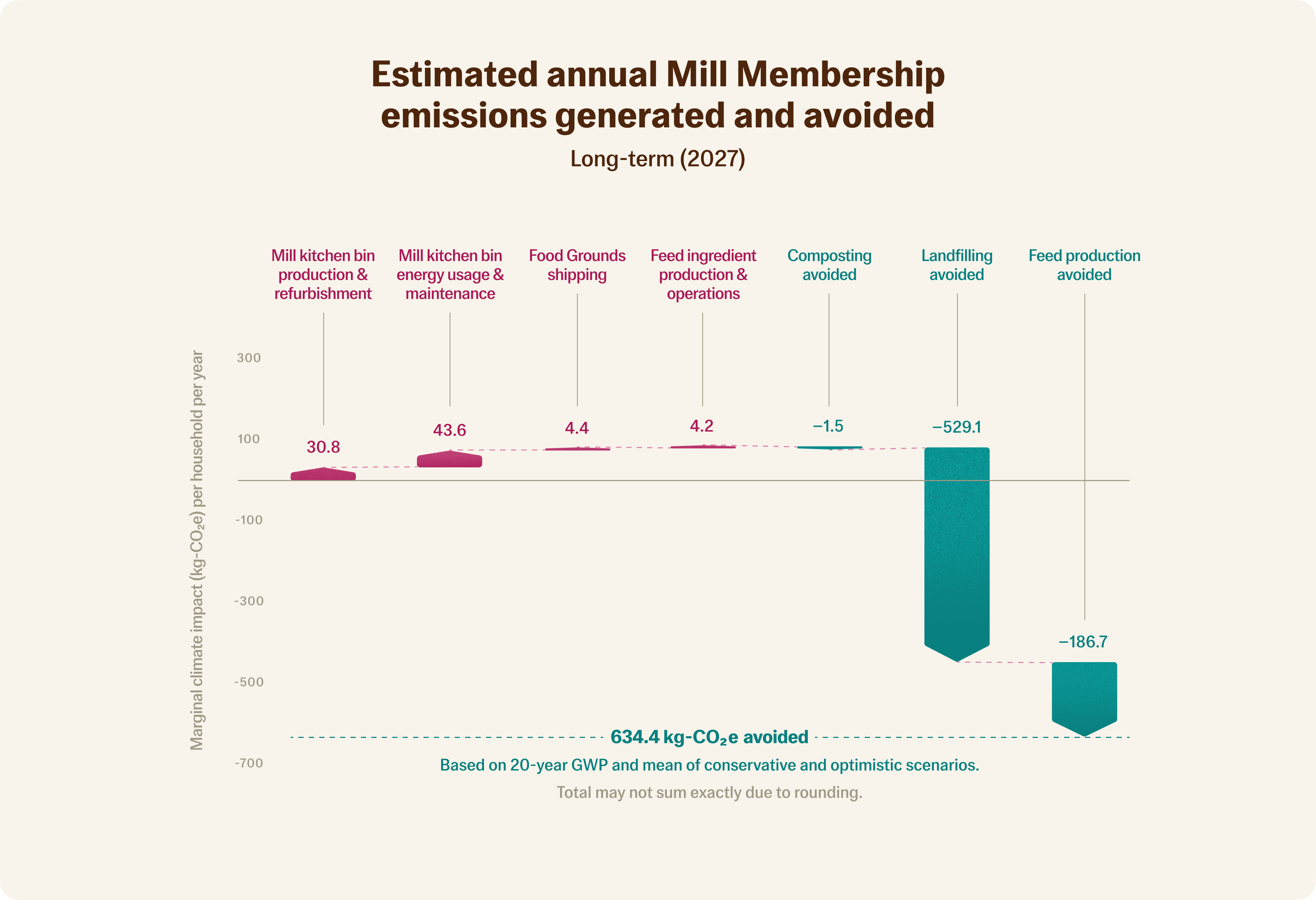

Findings

1

Operations

Assumptions

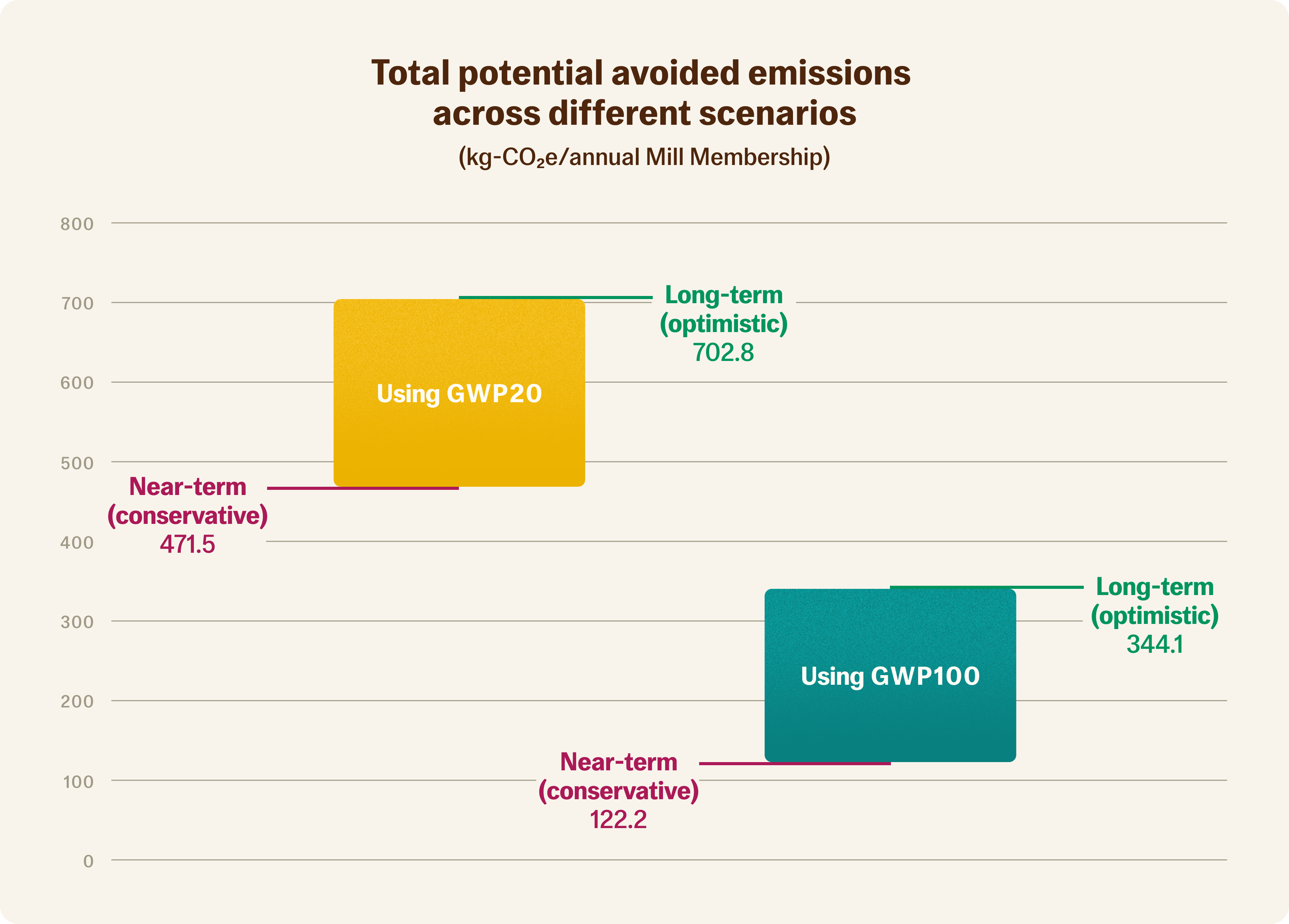

Avoided emissions (kg-CO2e per annual Mill Membership) using GWP20

2

Near-term

Conservative

471.5

3

Near-term

Optimistic

570.6

4

Near-term

Mean

521.1

5

Long-term

Conservative

565.9

6

Long-term

Optimistic

702.8

7

Long-term

Mean

634.4

There are no rows in this table

Future opportunities

Technical appendix

Phased approach

Exclusions

Key assumptions

1

Parameter

Near-term (2023) conservative

Near-term (2023) optimistic

Long-term (2027) conservative

Long-term (2027) optimistic

2

Device electricity use (long-term rolling mean, kWh/day)

0.852

(from field trial data)

0.75

(2023 target)

0.75

0.5

(2027 target)

There are no rows in this table

) because it assumes an aggressive approach to achieve a clean energy transition. We used different values for our two long-term scenarios because of significant uncertainty in the future U.S. grid mix.1

Parameter

Near-term (2023) conservative

Near-term (2023) optimistic

Long-term (2027) conservative

Long-term (2027) optimistic

2

Electric grid mix emission factor (kg-CO2e/kWh)

0.388

(U.S. 2021 mean)

0.388

(U.S. 2021 mean)

0.306

(EIA 2027 forecast)

0.138

(IEA 2027 forecast)

There are no rows in this table

1

Parameter

Value (constant across all scenarios)

2

Moisture content of kitchen scraps

72.2%

3

Carbon content of kitchen scraps

49.5%

4

Kitchen scraps-carbon to methane-carbon conversion yield

42%

5

Mass methane-C to mass methane

1.34

6

Landfill gas collection efficiency, national average for kitchen scraps

52%

7

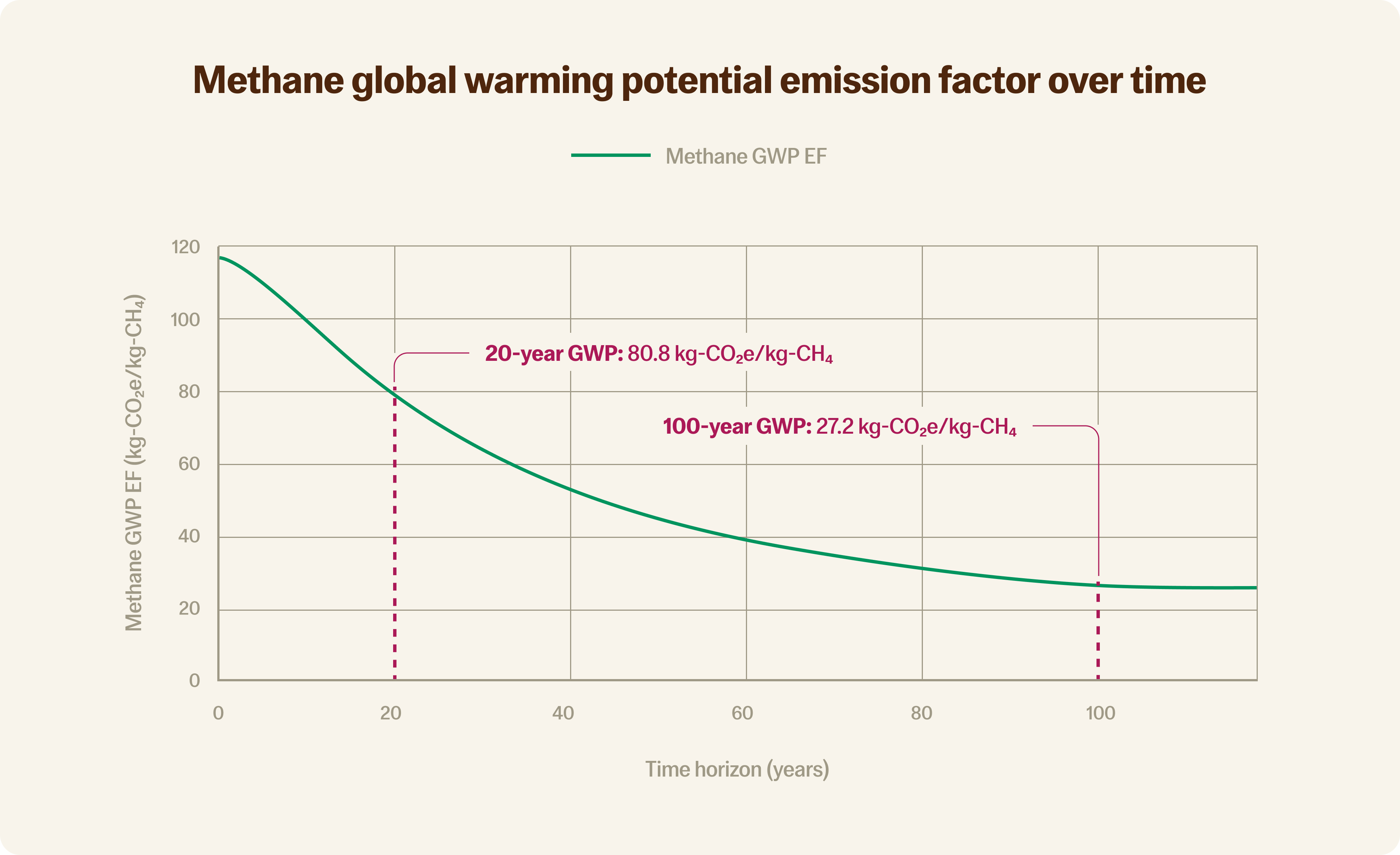

20-year (biogenic) methane global warming emission factor (GWP20)

80.8

8

100-year (biogenic) methane global warming emission factor (GWP100)

27.2

9

Counterfactual fate of kitchen scraps: %-landfilled

80%

10

Counterfactual fate of kitchen scraps: %-composted

20%

There are no rows in this table

1

Parameter

Value (constant across all scenarios)

2

Kitchen scraps generation rate (lbs-wet scraps/household/day)

1.326

There are no rows in this table

References

Want to print your doc?

This is not the way.

This is not the way.

Try clicking the ⋯ next to your doc name or using a keyboard shortcut (

CtrlP

) instead.