Skip to content

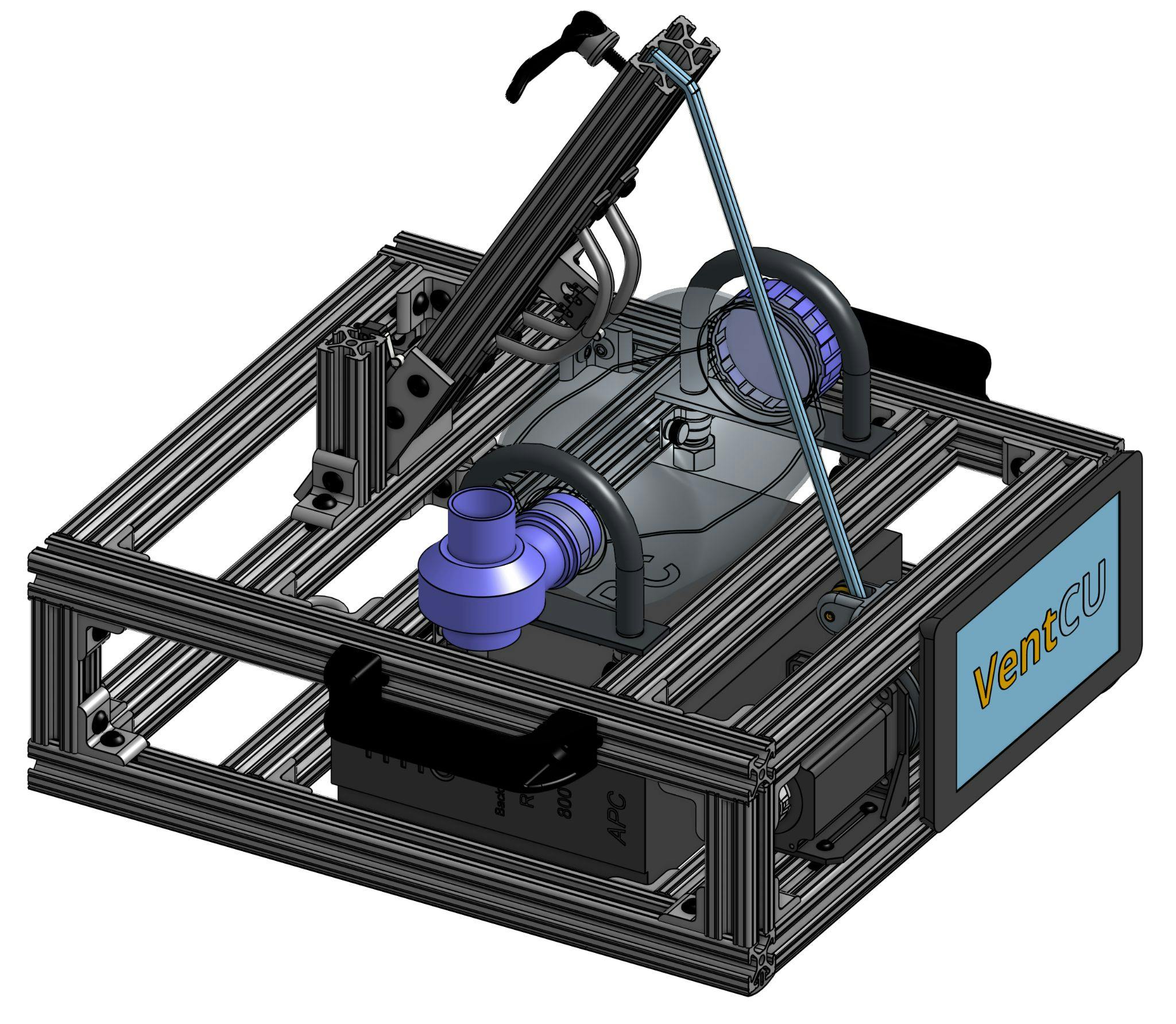

The Design

Limitations & Future Work

Limitations & Future Work

Overview

Motor Selection Re-evaluation

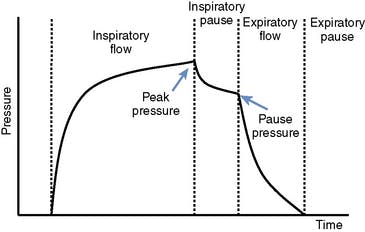

Pressure Sensor Data Collection

PCB Development

Battery Addition

Control System

Next: |

Want to print your doc?

This is not the way.

This is not the way.

Try clicking the ⋯ next to your doc name or using a keyboard shortcut (

CtrlP

) instead.